Laser Engraving Job Works In Chennai

Laser Engraving Job Works In Chennai – Royal Tech Engineering gives a prominent service of top-quality Laser Engraving Job Works In Chennai.

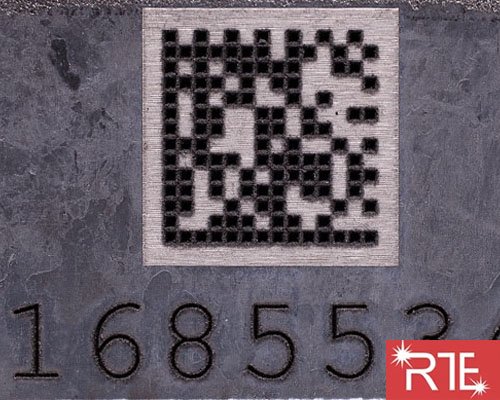

Royal Tech Engineering is the best laser engraving job works in Chennai. Laser Engraving Job Works is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial laser engraving job works applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics.

Our Quality Laser Engraving Job Works In Chennai

The laser engraving job works and CNC (computer numerical control) are used to direct the laser beam to the material. A commercial laser engraving job works for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

Laser cutter benefits include:

- Rapid processing times of engraving laser job work

- Reduced energy consumption & bills – due to greater efficiency.

- Greater reliability and performance – no optics to adjust or align and no lamps to replace.

- Minimal maintenance.

- The ability to process highly reflective materials such as copper and brass.

- Higher productivity – lower operational costs offer a greater return on your investment.

FAQ’S?

What does laser marking do?

Laser marking can mark a variety of materials such as steel, aluminum, stainless steel, polymers, and rubber.

Is laser marking permanent?

In simplest terms, laser marking is a permanent process that uses a beam of concentrated light to create a lasting mark on a surface. Typically performed with a fiber, pulsed, continuous wave, green, or UV laser machine, laser marking encompasses a wide variety of applications.

How is laser cutting priced?

The laser cutting costs are based on the time your file takes to cut in the laser.

How deep is laser marking?

When it comes to deep engraving, the depth can easily reach a few millimeters into metals.

How fast is laser marking?

Laser marking machines have always been considered very fast devices at various marking speeds, but they also have limitations. The theoretical speed of the manufacturer is 9000mm/s, and some marking opportunities are lower than this speed, about 7000mm/s.

Can laser engraving fade?

Soft metals such as copper, brass and aluminium are more prone to engraving fading than harder metals such as stainless steel and other materials. For glass engraving, the quality of the glass will affect longevity.