Micro Welding Service in Chennai

Micro Welding Service in Chennai–Royal Tech Engineering is a highly skilled and take full safety measures of Micro Welding service in Chennai.

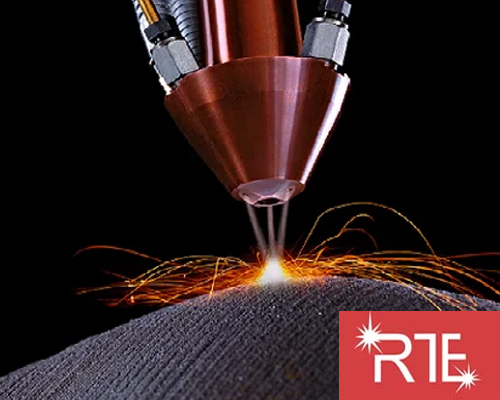

Micro Welding Service in Chennai – Royal Tech Engineering is the best Micro Welding Service in Chennai. Micro welding is a process that uses heat to join two materials together for micro components. It’s frequently used for molds, dies, surgical devices, and in the aerospace, gas, oil, and automotive industries because it produces a precise and stronger bond than traditional methods while keeping heat input to a minimum.

There are 4 types of micro-

- Welding Currently In Practice;

- Micro-Laser Welding,

- Tig Micro-Welding,

- Flash Micro Welding And,

- Micro-Resistance Welding.

Precision welding requirements are met with this kind of micro resistance welding machines. Micro size wires need precise positioning the highest weld quality for ensuring uninterrupted operations. These are designed for delivering reliable joints repetitively and don’t need a highly trained operator.

Available with more optional accessories to increase machine performance such as pedestal trolley, shearing attachment, magnifying glass, and lamp attachment, etc. We are butt welding machine and wire products manufacturers with an experience of over 20+ years. We have developed customized solutions for but welding and various wire product applications including automobile seat, gasket components, modular kitchen accessories, wire baskets, cable try, sport safety wire products, bottle holders for Indian Railway, road transportation, display racks, wire shelf, wire hangers, kitchen products, etc.

FAQ’S?

What does laser marking do?

Laser marking can mark a variety of materials such as steel, aluminum, stainless steel, polymers, and rubber.

Is laser marking permanent?

In simplest terms, laser marking is a permanent process that uses a beam of concentrated light to create a lasting mark on a surface. Typically performed with a fiber, pulsed, continuous wave, green, or UV laser machine, laser marking encompasses a wide variety of applications.

How is laser cutting priced?

The laser cutting costs are based on the time your file takes to cut in the laser.

How deep is laser marking?

When it comes to deep engraving, the depth can easily reach a few millimeters into metals.

How fast is laser marking?

Laser marking machines have always been considered very fast devices at various marking speeds, but they also have limitations. The theoretical speed of the manufacturer is 9000mm/s, and some marking opportunities are lower than this speed, about 7000mm/s.

Can laser engraving fade?

Soft metals such as copper, brass and aluminium are more prone to engraving fading than harder metals such as stainless steel and other materials. For glass engraving, the quality of the glass will affect longevity.