Laser Welding Job Works In Chennai

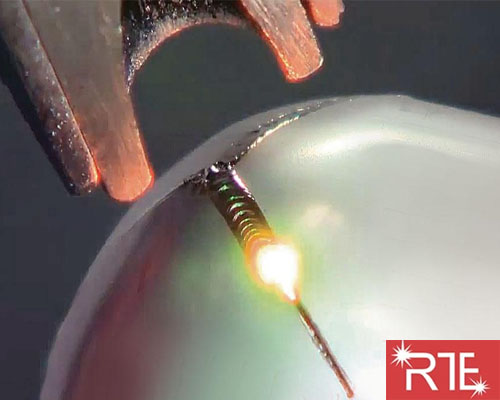

Laser Welding Job Works In Chennai – Royal Tech Engineering gives a prominent service of top-quality Laser Welding Job Works In Chennai.

Laser Welding Job Works in Chennai- Royal Tech Engineering offering for Laser welding job works includes hot-air hand tools, extruders and welding machines, including a wide range of accessories for DIY and Industrial markets. Analyze, review & monitor the capacity of the production line with respect to Demand Utilization on half yearly/Annually based on laser welding job works Plan. Execute capacity ramp up plan considering the equipment, machines, toolings, jigs, fixture requirement for assembly line.

Chennai Laser Welding Job Works we’re Proud of

Thanks to our more than 25+ years of experience, we offer jobs and services that set standards in your respective fields of expertise. Whether you use Leister welding equipment for floor installations, roofing, landfills, tunnels, aquatics or other, you can rely on the innovative, durable and efficient for laser welding job works in Chennai.

we are nearby all over Chennai. We support your plastic welding needs in multiple applications for job works: From flooring and roofing, to geomembranes, plastic fabrication and much more.

This position will be responsible for performing Process analysis, Process improvements, process sustenance, analysis of yield/quality related issues on assembly cells for all the existing & new products. He will be handling Quad & Switch assembly & sub assembly lines.

FAQ’S?

What does laser marking do?

Laser marking can mark a variety of materials such as steel, aluminum, stainless steel, polymers, and rubber.

Is laser marking permanent?

In simplest terms, laser marking is a permanent process that uses a beam of concentrated light to create a lasting mark on a surface. Typically performed with a fiber, pulsed, continuous wave, green, or UV laser machine, laser marking encompasses a wide variety of applications.

How is laser cutting priced?

The laser cutting costs are based on the time your file takes to cut in the laser.

How deep is laser marking?

When it comes to deep engraving, the depth can easily reach a few millimeters into metals.

How fast is laser marking?

Laser marking machines have always been considered very fast devices at various marking speeds, but they also have limitations. The theoretical speed of the manufacturer is 9000mm/s, and some marking opportunities are lower than this speed, about 7000mm/s.

Can laser engraving fade?

Soft metals such as copper, brass and aluminium are more prone to engraving fading than harder metals such as stainless steel and other materials. For glass engraving, the quality of the glass will affect longevity.